Injection molding sliders or lifters allow a part to be released from an injection mold by releasing it. Slides or sliders are used to release any external undercuts or recesses…

Injection molding sliders or lifters allow a part to be released from an injection mold by releasing it. Slides or sliders are used to release any external undercuts or recesses…

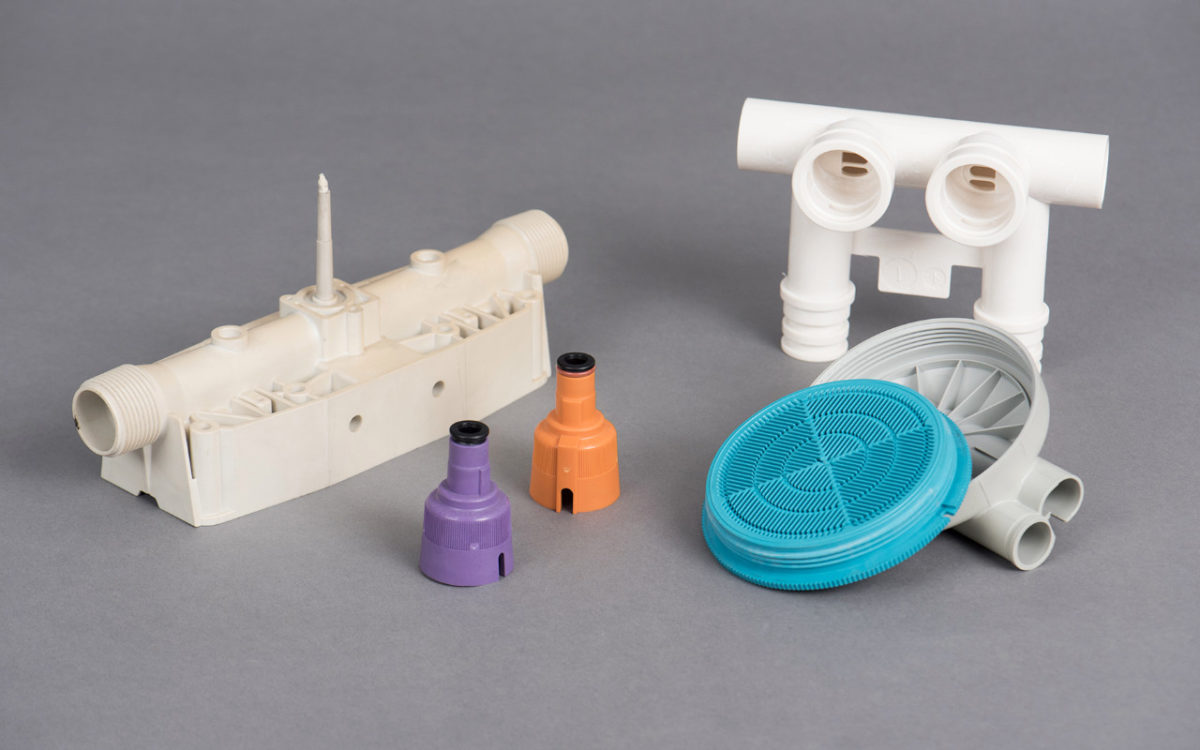

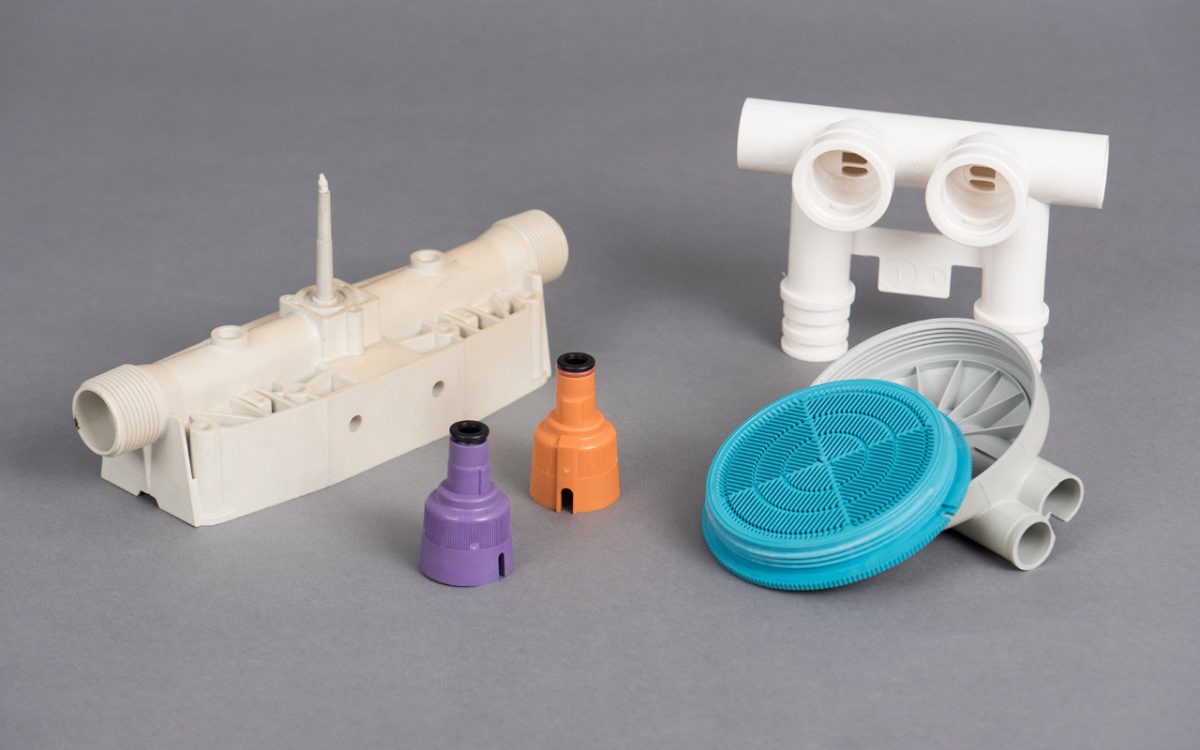

Plastic injection molding can be used to produce many parts. It offers many advantages over other methods of plastic molding. It is more reliable, simple, and efficient than other methods…

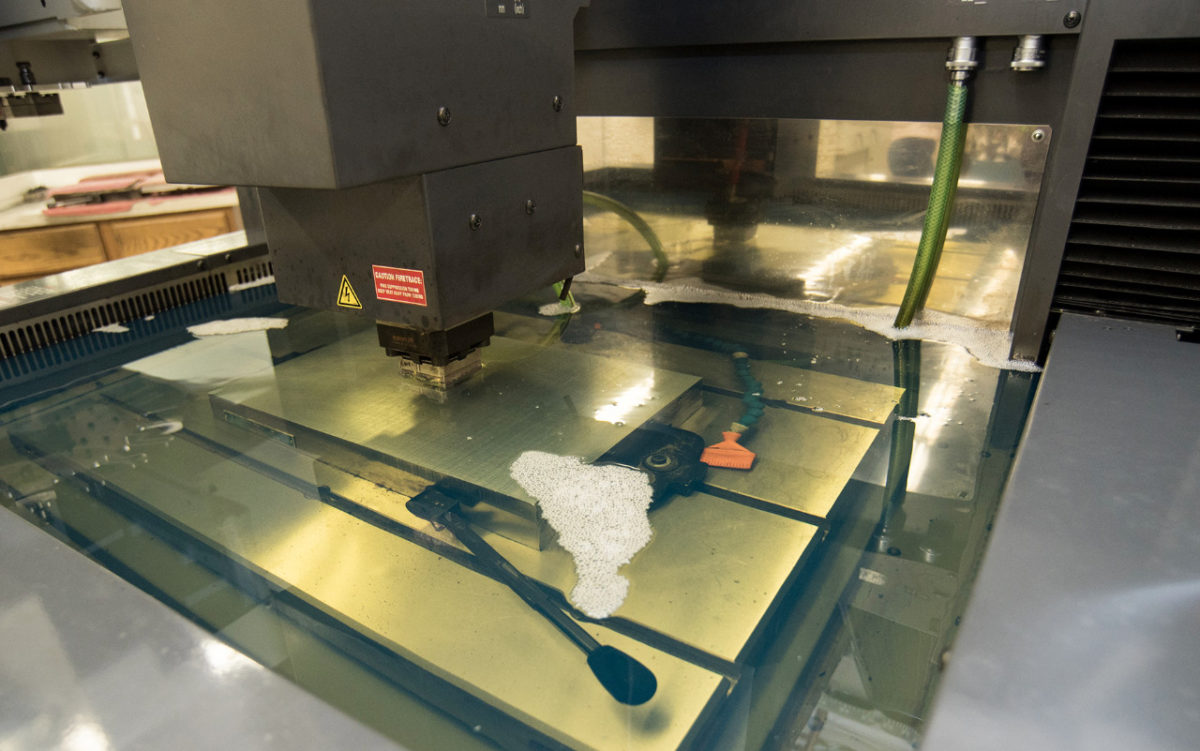

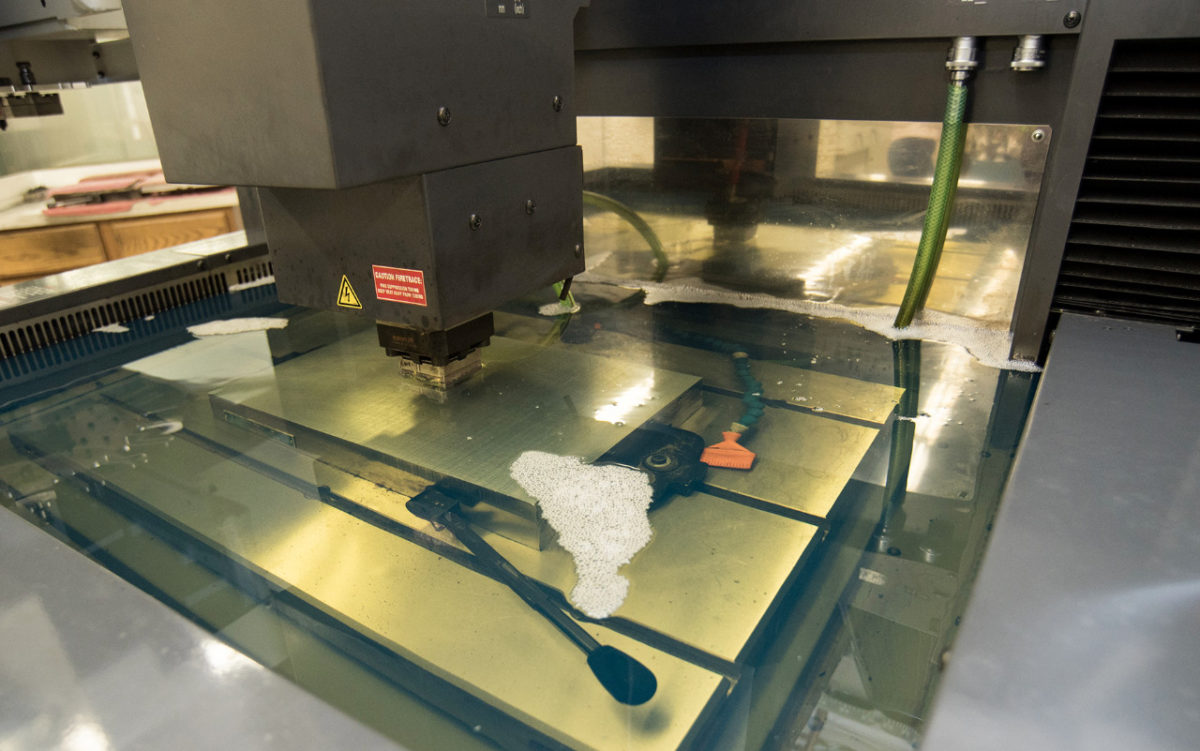

Precision tooling, which is well-engineered and designed, is key to high quality stamped parts. Preferred Tool has a state of the art, in-house tool-making plant that allows us to have…

Injection molding is fundamentally based on its tooling. Plastic injection tooling – more specifically, tooling design – determines the quality of the injection molding process and the parts produced, regardless…

When it comes to injection molds, the Preferred Tool is the best in the industry. People recognize that this company provides the finest tooling equipment. Since this is common knowledge,…

Custom molds are needed across all industries for a variety of tasks. In order to create the mold that will best meet your demands, you need a business that pays…

Preferred Tool is a specialized procedure that allows for the precise and accurate production of parts. This method is extremely efficient, straightforward, and cost-effective. The majority of businesses employ this…

It is well known that aluminum is a popular raw material for manufacturing. Rapid prototyping is also very popular with engineers for new products. How does Aluminum Rapid Prototyping work?…

The injection molding process is known for its ability to produce large quantities of parts in a very efficient way. When there are thousands and millions of the same parts…

A car takes how long to build? A house takes how long to build? How long does it take to develop a new product? It depends, is the short answer….

Recent Comments