Plastic injection molding is a technique for creating a wide range of complicated plastic parts and components. OEMs in a variety of industries can profit from the approach. It’s known…

Plastic injection molding is a technique for creating a wide range of complicated plastic parts and components. OEMs in a variety of industries can profit from the approach. It’s known…

How does MIM stack up against other production methods? Metal Injection Molding is ideally suited to the production of high-volume complicated metal components with a net shape that fits comfortably…

Preferred Tool is a specialized procedure that allows for the precise and accurate production of parts. This method is extremely efficient, straightforward, and cost-effective. The majority of businesses employ this…

How can a prototype be manufactured if injection molding is a manufacturing process? Our definition of injection molded prototypes at Preferred Tool is several hundred to a thousand pieces created…

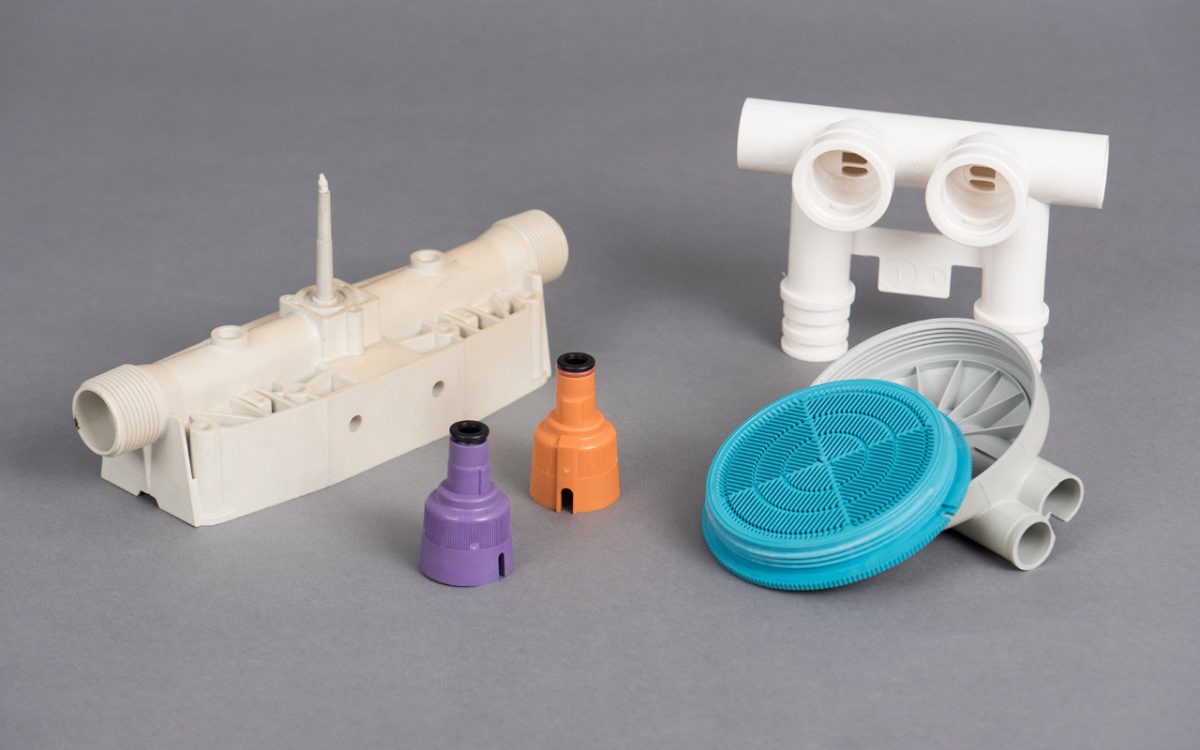

Due to its ability to quickly produce a large number of identical parts from a single mold without sacrificing quality, plastic injection molding is one of the most widely used…

Products made with plastic injection molding include automotive and airplane components, storage containers, musical instrument parts, and hair combs. It is one of the most widely used manufacturing processes because…

It is well known that aluminum is a popular raw material for manufacturing. Rapid prototyping is also very popular with engineers for new products. How does Aluminum Rapid Prototyping work?…

The injection molding process is known for its ability to produce large quantities of parts in a very efficient way. When there are thousands and millions of the same parts…

A car takes how long to build? A house takes how long to build? How long does it take to develop a new product? It depends, is the short answer….

Injection molding is a complex and difficult process that doesn’t always produce products that match the original developer’s vision. Variables abound, and product designers don’t always consider injection molding guidelines,…

Recent Comments