Plastic injection molding is one of the most widely used methods for producing plastic parts, and for good reason. It offers numerous advantages over other plastic molding methods, making it…

Plastic injection molding is one of the most widely used methods for producing plastic parts, and for good reason. It offers numerous advantages over other plastic molding methods, making it…

Custom molds are needed across all industries for a variety of tasks. In order to create the mold that will best meet your demands, you need a business that pays…

Preferred Tool offers specialized plastic injection mold making, a reliable and efficient process for producing precise parts. This method is celebrated for its accuracy, versatility, and cost-effectiveness, making it an…

Plastic injection molding is a versatile and efficient manufacturing method widely used for producing parts and products across various industries. Its advantages over other plastic molding techniques make it a…

Advantages and Disadvantages of Injection Molding Efficient High Production Speed: Injection molding is highly efficient, especially after molds are developed. Cycle times can be as short as 10 seconds. Volume:…

Over-Molding Plastic Over-molding refers to the injection molding technique where a material (usually TPE) is molded on a second (usually rigid plastic) using heat, pressure and liquid silicone. TPE over-molding…

Attention to detail is key in all manufacturing. One of the most important details in injection molding is well-designed, precise and high-quality tooling. Injection mold tool is a mold or…

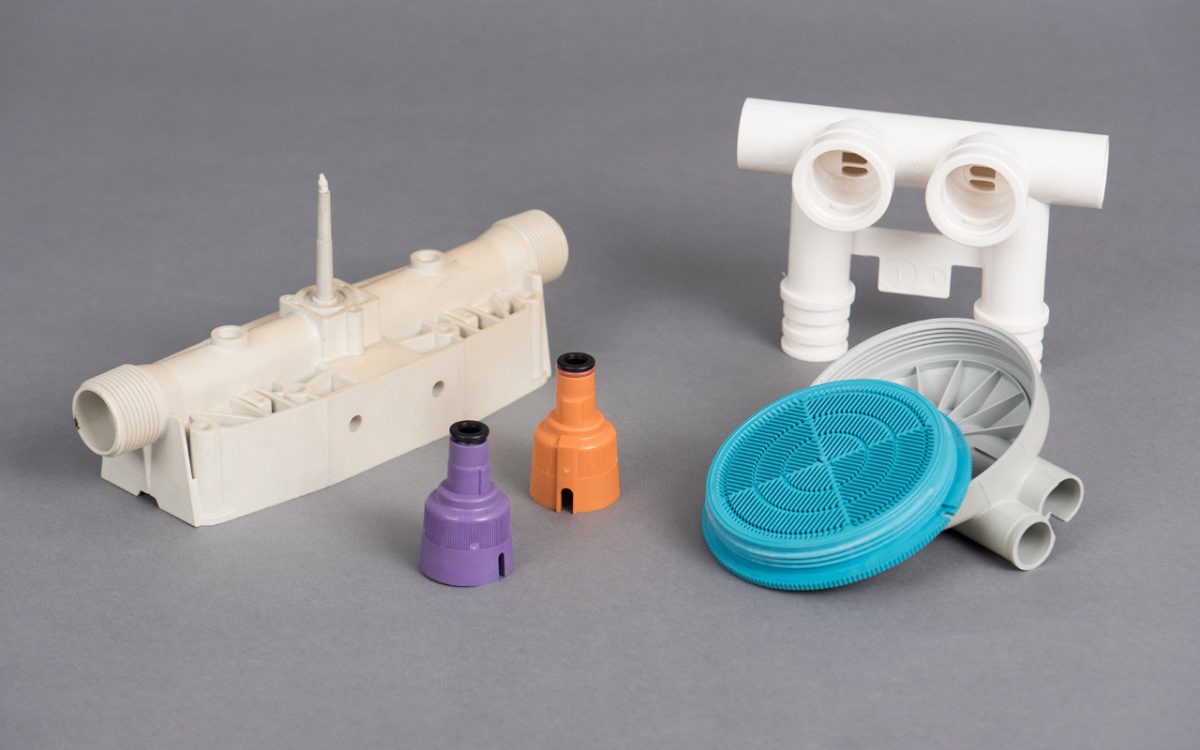

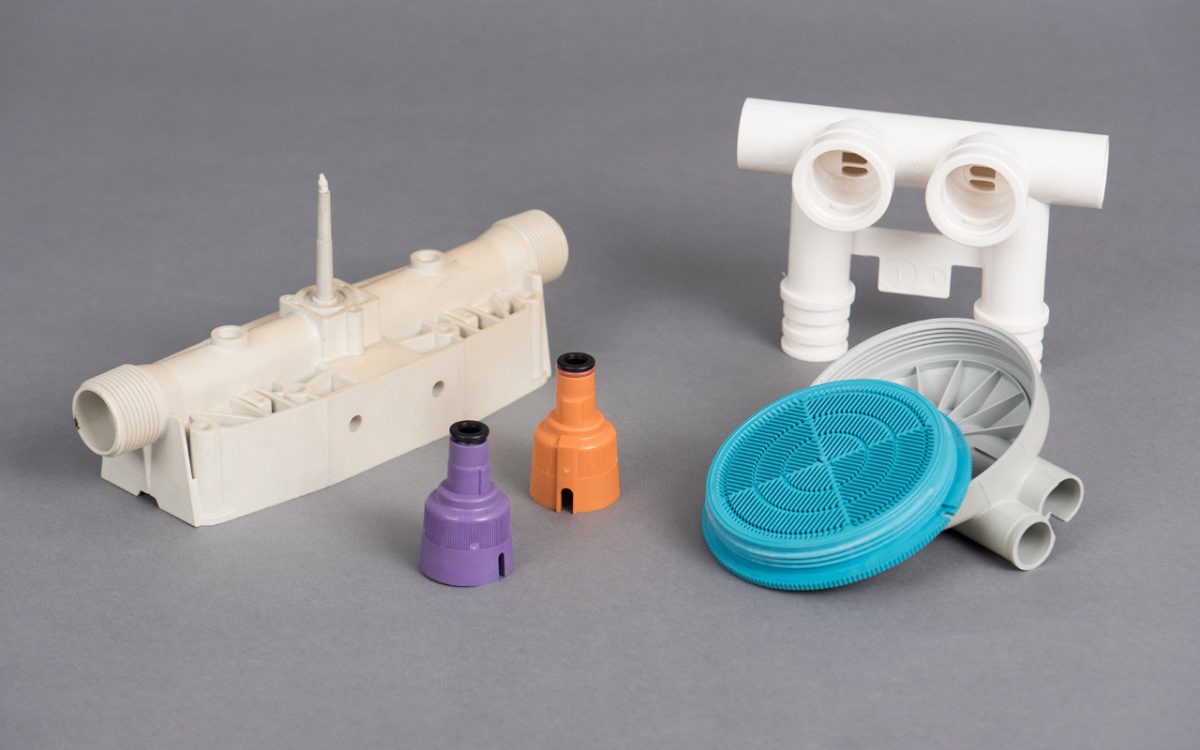

This process is very versatile, and it can be used to produce many different parts for various applications. You have a variety of options when creating a product requiring molded…

Tooling Services Plastic injection tooling involves the shaping and production of metal components that give a final shape to a product. To ensure that the mold’s core box and casting…

Injection molding is a process that can be used to create plastic parts in a variety of applications. This technique is dependent on a variety of materials and different types…

Recent Comments